Electric Gate Maintenance Costs Overview

Older gates may require more frequent repairs and part replacements, increasing maintenance expenses.

Materials like steel, aluminum, or wood impact maintenance needs and costs.

High-traffic gates tend to wear out faster, leading to higher maintenance costs.

| Factor | Impact on Cost |

|---|---|

| Gate Material | Different materials require varied maintenance and repair costs. |

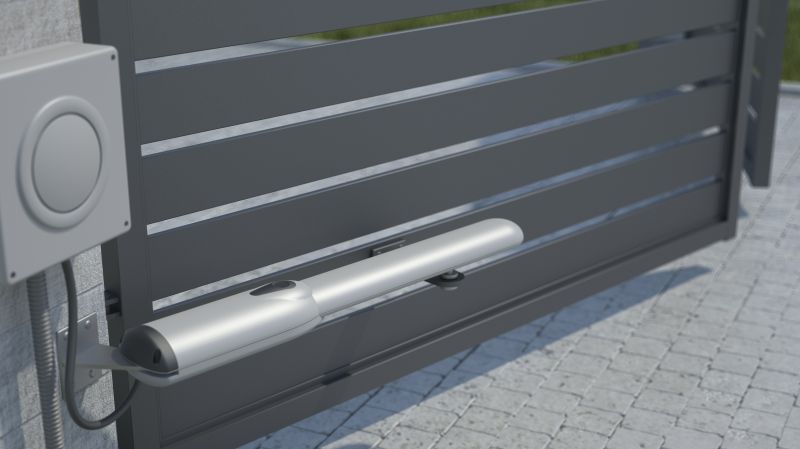

| Automation System | Complex systems may need specialized repairs and parts. |

| Frequency of Use | More frequent operation accelerates wear and tear. |

| Environmental Conditions | Exposure to weather elements can increase maintenance needs. |

| Age of Gate | Older gates may need more repairs and part replacements. |

| Type of Motor | High-powered motors may incur higher maintenance expenses. |

| Security Features | Additional features like sensors or cameras add to maintenance costs. |

| Service Provider Rates | Labor costs vary based on service provider and location. |

The expenses associated with electric gate maintenance can vary widely depending on the specific factors involved. Routine inspections and preventive maintenance typically cost less than emergency repairs or system upgrades. Regular servicing can help identify potential issues early, potentially reducing long-term costs. The choice of materials, the complexity of automation systems, and environmental exposure all influence the frequency and cost of repairs. Proper maintenance ensures reliable operation and can extend the lifespan of the gate, but it requires a consistent budget allocation based on the gate's characteristics and usage patterns.

Specific components inside electric gates, such as motors, sensors, and control panels, are critical to operation and can significantly impact maintenance costs. Motors may require lubrication, part replacements, or rewinding over time, especially with frequent use. Sensors and safety devices need calibration and occasional replacement to ensure proper functioning. Control panels and circuitry can be affected by power surges or environmental factors, leading to repair or replacement expenses. Regular inspections and timely repairs are essential to maintain optimal performance and prevent costly breakdowns.

Motors are vital for gate movement and may require lubrication, rewinding, or replacement over time.

Sensors ensure safe operation and may need calibration or replacement periodically.

Control systems manage gate operations and can incur costs due to repairs or upgrades.

| Service Type | Average Cost |

|---|---|

| Routine Inspection and Maintenance | $150 - $300 |

| Motor Repair or Replacement | $200 - $800 |

| Sensor Calibration or Replacement | $100 - $250 |

| Control Panel Repair | $250 - $600 |

| Lubrication and Mechanical Adjustments | $100 - $200 |

| Emergency Repair Services | $300 - $1,000 |

| System Upgrade or Modernization | $1,000 - $3,000 |

| Battery Replacement (if applicable) | $50 - $150 |

| Safety Device Calibration | $100 - $200 |

| Wiring and Electrical Repairs | $150 - $400 |